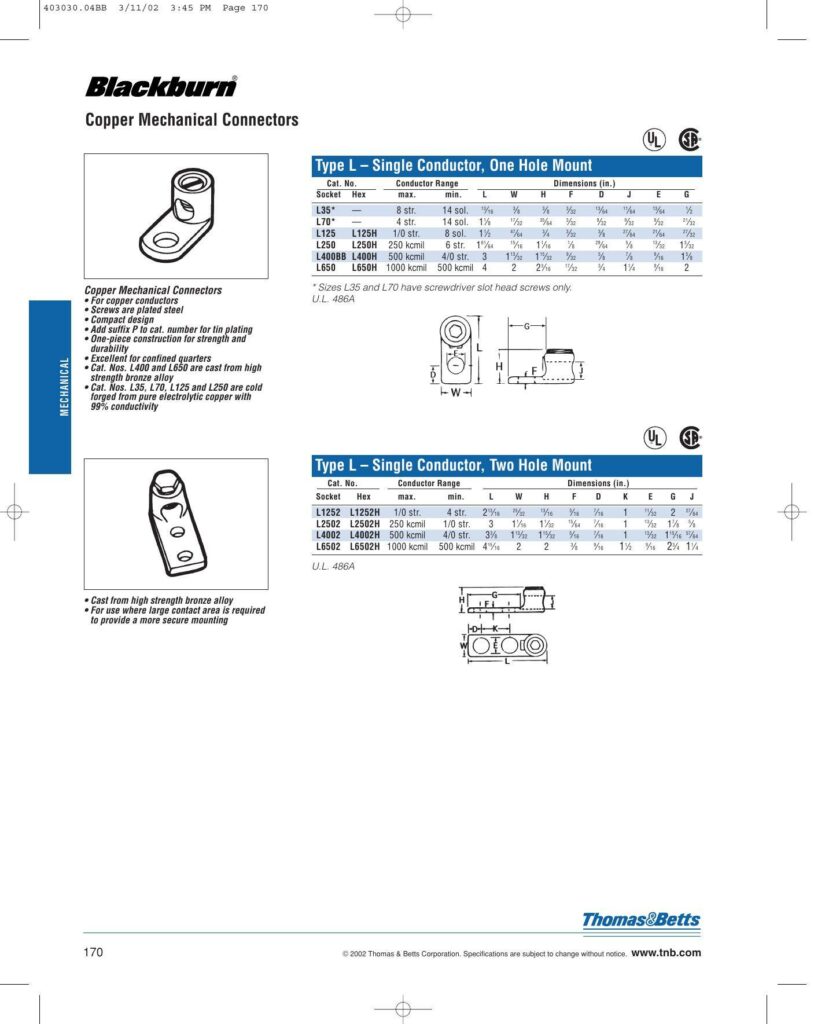

This datasheet provides detailed information about the Blackburn Copper Mechanical Connectors, which are used for copper conductors. The connectors are categorized into two types: Single Conductor, One Hole Mount (Type L) and Single Conductor, Two Hole Mount (Type L2).

Product Features

Connectors in this line are designed with a compact design and are ideal for use in confined spaces. The connectors offer strong and durable one-piece construction. For enhanced connectivity, most of the units are made from pure electrolytic copper which ensures 99% conductivity, while others are cast from a high-strength bronze alloy for additional toughness.

Some connectors are specially treated with a finish; for tin plating, users can append a ‘P’ to the catalog number when ordering. The screws used in these connectors are made from plated steel for added durability.

Product Specifications

Each connector variant is listed with its catalog number and acceptable conductor range, measured by American wire gauge (AWG) sizes that range from a maximum of 1000 kcmil to a minimum of 14 solid. The datasheet also details the dimensions for each part including the length, socket size, and hex size to assist with installation and compatibility.

Cat. Nos: L35, L70, L125, and L250 are designed specifically for single-conductor, one-hole mount applications. Item L125 additionally comes in a version with a high-tongue (denoted as L125H), to facilitate different installation needs.

For the two-hole mount design, compatible Cat. Nos are L1252/L1252H, L2502/L2502H, L4002/L4002H, and L6502/L6502H. These connectors are cast from bronze alloy when large contact areas are required, which implies their usability in applications that demand a more secure mounting. The document denotes a similar high-tongue offering in these categories as well, represented by appending an ‘H’ to the catalog numbers.

Units like L35 and L70 are equipped with screwdriver slot head screws only. The datasheet notes that these connectors comply with the standard U.L. 486A, a certification for safety and reliability in splicing wire connectors.

Corporate Details

The datasheet concludes with a statement from the manufacturer, Thomas & Betts Corporation, noting that these specifications are modern as of 2002, but are subject to change without notice. This signifies that users should consult the most recent product information, potentially available on the company website.

References:

Download: Blackburn Copper Mechanical Connectors

Chat: Powered By VoiceSphere

Pricing & Distributors: https://www.datasheets360.com/part/detail/l250h/2479357510222894138/