Wire-to-Wire Splicing SolderSleeve wire splices

Transparent polyvinylidene fluoride or polyolefin sleeve provides encapsulation, inspectability, strain relief, and insulation.

Applications

In-line wire splices

Features and Benefits

Prefluxed solder preform provides controlled soldering process

One-piece design makes installation easy and lowers the installed cost

Meets 75,000 ft (22,000-m) altitude immersion requirement

Thermochromic temperature indicator in the NAS splices facilitates termination and inspection

UL and CUL recognized

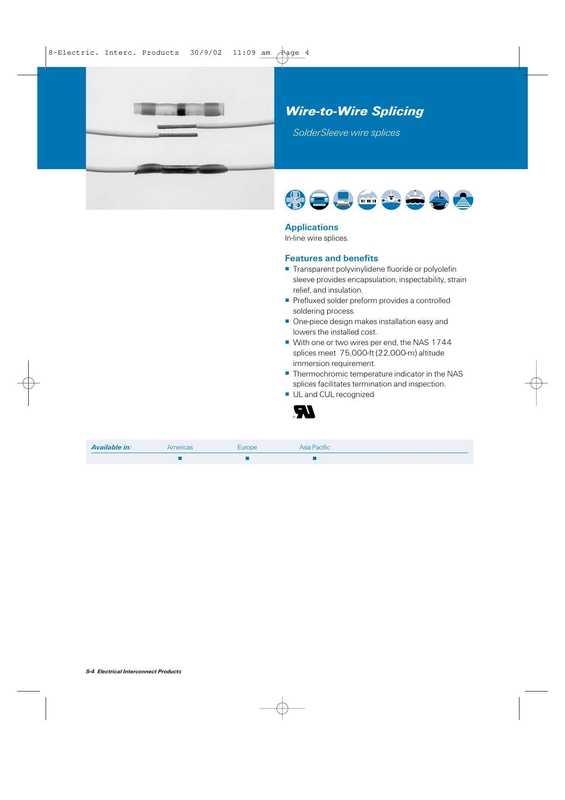

Product Options

Select the product series appropriate for your application based on the temperature rating and sealing performance required.

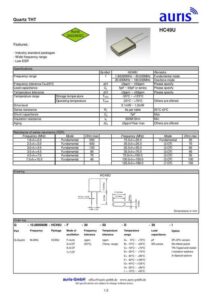

Notes

While all combinations listed will provide satisfactory solder joints, the degree of strain relief obtained depends on the outer diameter of the wires being joined.

Refer to Table E for the recommended size ranges for the sleeves.

Manual:

Chat: Powered By VoiceSphere

Pricing & Distributors: https://www.datasheets360.com/part/detail/d-110-0090/-4494858912504947731/