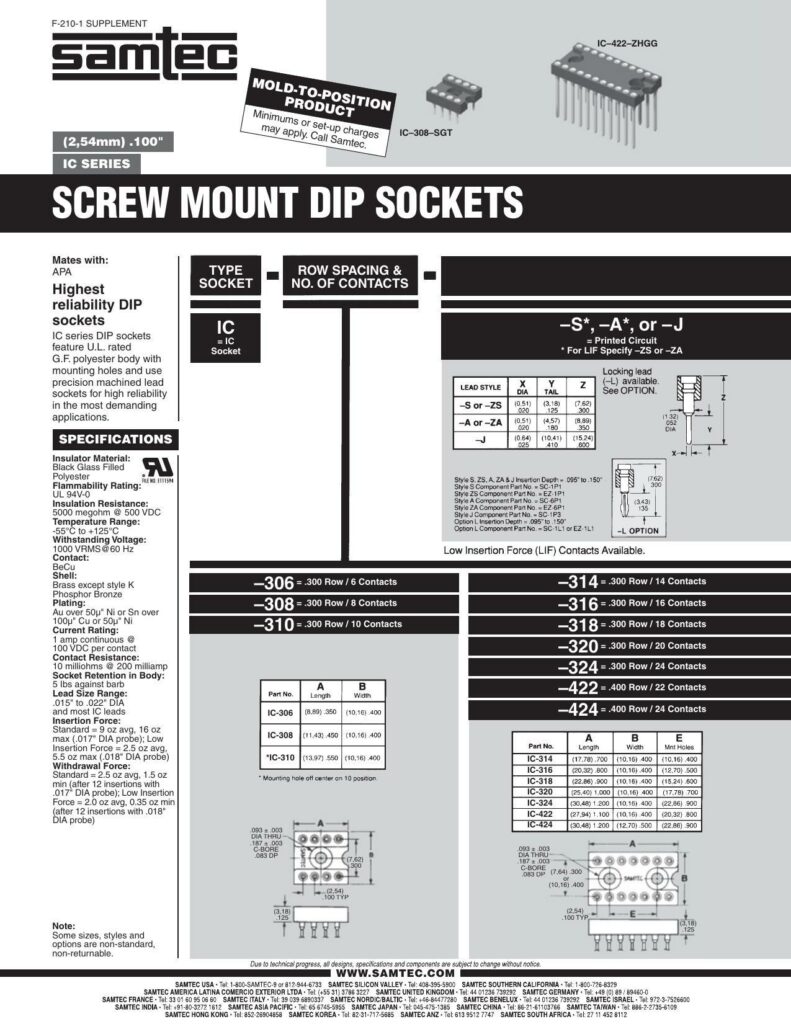

Overview

The datasheet focuses on Samtec’s IC SERIES Screw Mount DIP Sockets, which are termed as high-reliability DIP sockets ideal for demanding applications. Details provided in the datasheet specify the design, key features, specifications, and available options for the sockets, including various models and configurations.

Construction and Design

Constructed with a UL-rated GF (glass-filled) polyester body, these DIP sockets are designed for secure PCB mounting as they feature precision-machined lead sockets. The sockets support different lead styles and dimensions, accommodating a wide range of IC leads with a clear emphasis on mechanical reliability and electrical performance. The body of the socket has multiple mounting holes integrated for screw mounting, increasing their sturdiness on the printed circuit boards.

Specifications

The datasheet provides comprehensive technical details:

- Materials: The insulation is made from black glass-filled polyester, with a flammability rating of UL 94V-0.

- Contact: Beryllium copper (BeCu); shell is either brass or, for style K, phosphor bronze.

- Plating: Options include gold over 50µ” nickel or tin over 100µ” copper or 50µ” nickel.

- Insulation Resistance: A notable 5000 megohms at 500 VDC.

- Temperature Range: Operating range is between -55°C to +125°C.

- Withstanding Voltage: These sockets can withstand 1000 VRMS at 60 Hz.

- Current Rating: A continuous current rating of 1 Amp per contact.

- Contact Resistance: Low resistance of 10 milliohms at a current of 200 milliamps.

- Socket Retention in Body: A strong retention force of 5 lbs against the barb.

Electrical Performance

The DIP sockets’ electrical performance is highlighted with an insulation resistance of 5000 megohms at 500 VDC and a contact resistance of 10 milliohms at 200 milliamps. The sockets are also able to endure a withstanding voltage of 1000 VRMS at a frequency of 60 Hz.

Mechanical Characteristics

Mechanical attributes include lead size range, insertion and withdrawal forces, and variations for low insertion force requirements. The typical lead size range is from .015″ to .022″ in diameter. For the insertion force, the standard is 9 Oz average, with a maximum of 16 Oz for the .017″ DIA probe, while the low insertion force variation averages 2.5 Oz with a maximum of 5.5 Oz for the .018″ DIA probe. Withdrawal force averages at 2.5 Oz with a minimum of 1.5 Oz after 12 insertions for the standard sockets, and 2.0 Oz average with a 0.35 Oz minimum for the low insertion force sockets.

Part Numbering and Options

The datasheet lists various part numbers along with the corresponding row spacing and number of contacts (e.g., IC-306, IC-308, IC-310, up to IC-424). It also specifies the different lengths and widths of the sockets and notes that some sizes, styles, and options may be non-standard and non-returnable.

Support and Availability

There is a mention of potential non-standard sizes and options that are non-returnable, indicating that customization is available. For customer support and purchase, contact information for Samtec offices around the globe is provided including Samtec USA, Samtec Silicon Valley, Samtec Southern California, Samtec América Latina, and several others across Europe, Asia, and Africa.

Disclaimer

The datasheet concludes with a notice about how designs, specifications, and components are subject to change without notice due to technical progress.

Manual:

Chat: Powered By VoiceSphere

Pricing & Distributors: https://www.datasheets360.com/part/detail/ic-422-sst/352530521768951888/