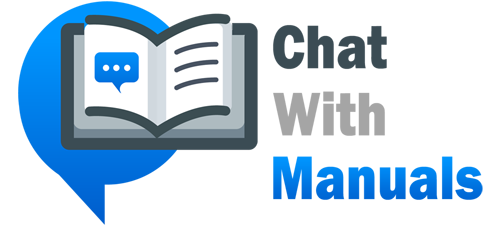

Overview of King’s Electronics KA-511/B Drawing

The content seems to be extracted from the technical drawing and specification datasheet for components designed or manufactured by King’s Electronics. The datasheet, identified as Drawing No KA-51-/8 SD, features information on various electronic components such as connectors, C-Ring, clamp, body, etc., that are likely part of a larger electronic or mechanical product.

The datasheet presents a detailed list of parts such as the TNC Plug 704-5-HC7, alongside proprietary part number identification like ER 6355 and 7892, indicating revisions and alterations that have been noted across different dates ranging from August 1968 to May 1974, showcasing the document’s utility in recording changes and parts status over time. These parts have specific descriptions, mechanical properties, dimensions, and possibly materials indicated for each referenced number.

Detailing and Specifications

The specific information on certain parts, for example, “704-6 499 LEAA E9R BATE 22Avab&” and “KINGS ELECTRONICS 40 HARALIDALI RAaD 7EZTc7 TUcKahOE # {0707,” suggests a mix of coding that could relate to part series, design models, certifications, date codes, or addresses related to the manufacturer. The presence of a name, “Bushi< ZSUETOR BNc," may indicate an engineer, inspector, or related professional responsible for the component or document.

Tolerances are mentioned to be tight, with “break sharp edges .005 Max” and roughness to be “32 microinches RMS MAX” which designate the precision required in the manufacturing of these components. It is indicated that dimensions are in decimals and angles measurement tolerances of ±0′ 30″ are permitted.

Manufacturing and Quality Assurance Notes

Particularly noteworthy is the directive “Prior to plating do not damage if making ‘u4t”, which suggests a finishing process step wherein the component would be plated—potentially for corrosion resistance, solderability, or conductivity—and that care must be taken not to damage the part during this phase.

From the partial text presented, the emphasis is on precise manufacturing tolerances, quality assurance measures, and traceability of changes and specifications, which is typical for parts used in precision applications, potentially within aerospace, military, or high-reliability fields.

Conclusion

In sum, the document appears to be a specialized resource aimed at quality control, assembly, or manufacturing personnel who need to understand the detailed specifications and revisions for components associated with King’s Electronics. While truncated, the text demonstrates attention to detail imperative for components where performance and compliance to exacting standards are critical.

References:

Chat: Powered By VoiceSphere

Pricing & Distributors: https://www.datasheets360.com/part/detail/ka-51-18/7963645884693628259/