Overview

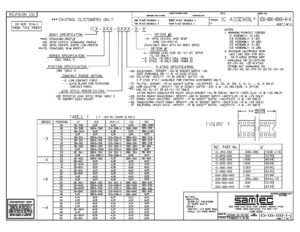

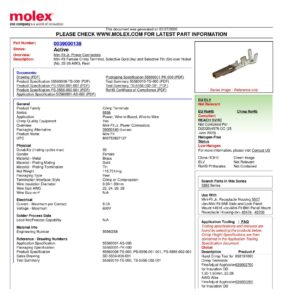

The ICA-320-SGT datasheet presents comprehensive information about Automated Insertion Dual Inline Package (DIP) Sockets designed for compatibility with IEEE standard I/O ports. These sockets are suitable for space-saving applications due to their open body design and the ability to be stacked side by side and end to end. They feature a 2.54mm (0.100″) contact and row spacing with various styles and plating options, enhancing their adaptability for different design needs.

Product Features

The sockets come with a variety of options for row spacing and the number of contacts, plating, and style. The ‘GG’ notation indicates a particular plating option, which comprises 30µ” (0.76µm) Gold contact and 10µ” (0.25µm) Gold shell. ‘GT’ offers the same Gold contact width but with a Tin shell instead. Additional variations include the ‘ST’ option with a 10µ” (0.25µm) Gold contact also paired with a Tin shell.

Customizable features also include options for wire-wrap tail lengths – with specific designations for shorter tails – as well as the locking lead option. The 322 series lacks a crossbar at one end which enables further design flexibility.

Technical Specifications

The sockets are characterized by high durability and performance under various conditions. The insulator material is Black Glass Filled Polyester FLF HC F41SP4, except for the -328 series that uses LCP. Contacts are made of BeCu, while shells are crafted from brass, with an option for gold or tin plating over 50µ” Nickel. The sockets are designed to provide a flame resistance rating of UL 94V-0 and offer an insulation resistance of 5000 MΩ minimum.

These DIP sockets are capable of operating in a wide temperature range, from -55°C to +105°C with tin and up to +125°C with Gold plating. They can endure a withstanding voltage of 1000V RMS and come with a current rating of 1A. The contact resistance is specified at 10mΩ maximum. Designed to accommodate a lead size range from 0.015″ (0.38mm) to 0.022″ (0.56mm) diameter, they also meet the needs for most integrated circuits.

Installation and maintenance are facilitated with a standard insertion force of 2 Oz average, up to 16 Oz maximum, and a withdrawal force of 2.5 Oz average, with a minimum of 1.5 Oz. These DIP sockets are suitable for wave soldering processes only and are fully RoHS compliant, ensuring adherence to current environmental standards for hazardous substances.

Contact Information

The datasheet concludes with contact information for Samtec, the manufacturer, including multiple international offices providing regional support.

References:

Download: ICA-320-SGT AUTOMATED INSERTION DIP SOCKETS

Chat: Powered By VoiceSphere

Pricing & Distributors: https://www.datasheets360.com/part/detail/ica-318-zagg/-5760516556192335283/