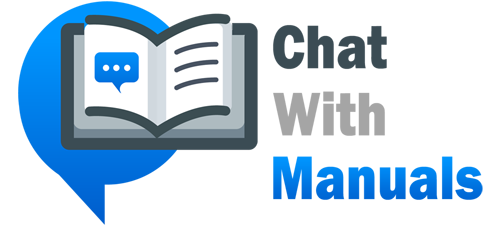

Overview of HT D-Sub High Temperature Connectors

The datasheet details HT D-Sub connectors which are designed to withstand high temperatures and are suitable for straight PCB (Printed Circuit Board) termination. These connectors are in compliance with MIL C24308 standards, signifying their suitability for military or industrial applications. Their construction includes a steel shell with nickel plating, an insulator made from glass-filled thermoplastic rated UL 94V-0, and boardlock and screwlock components made from brass with nickel plating. The contacts are crafted from a copper alloy with selective gold plating for reliable connectivity.

Electrical Specifications

The connectors boast a current rating of 5A and a voltage rating of 600V AC (rms) at 50Hz. They can withstand a voltage of 1000V AC (rms) at 50Hz for one minute, and come with an insulation resistance of 5000MΩ and a contact resistance of 10mΩ max. This robust design ensures secure and stable electrical connections even under demanding conditions.

Climatic and Mechanical Data

In terms of climatic resilience, these connectors operate reliably within a temperature range of -55°C to +150°C, and can withstand short-term exposure (up to 30 seconds) to temperatures as high as 260°C, which is often required during the reflow soldering process.

The mechanical data section lists the mating and unmating forces required for different numbers of contacts (15, 25, and 37), ensuring that users can gauge the ease of interaction with these connectors. For example, mating a 37-contact connector requires a maximum force of 12.51 kg (27.65 lb), while unmating requires a minimum of 1.1 kg (2.47 lb).

Industry Applications and Compliance

The HT D-Sub connectors are tailored for use in a wide range of industries, including industrial and telecommunications sectors, where standard connections are imperative. Moreover, these connectors are RoHS compliant, aligning with environmental regulations that restrict hazardous substances in electronic components.

Physical Dimensions and Ordering Information

The datasheet provides detailed dimensions for shell sizes, ensuring compatibility with various designs. Specific instructions for ordering, including configurations and plating thickness options (such as gold flash and 0.76 µm gold), are referenced in a chart titled “how to order”. Additionally, a recommended PCB layout is supplied to facilitate accurate integration into electronic systems.

References:

Chat: Powered By VoiceSphere

Pricing & Distributors: https://www.datasheets360.com/part/detail/l17htnahpol2rm81c/-9091692409316108020/